I have always been drawn to the understated elegance of lapel pins, especially those crafted with the die struck method. These little metal emblems are not mere decorations; they whisper quality and attention to detail in a way that printed pins simply cannot. I want to share some insights into the history, the complex manufacturing, and the best applications for die struck lapel pins. We will also examine how these pins differ from other kinds of metal lapel pins.

A Trip Down Memory Lane: The Story Behind Die Struck Pins

The story of die struck lapel pins is interwoven with the development of metalworking itself. The die striking technique, a method used for centuries to produce coins and medals, was celebrated for its accuracy and strength. As societies changed, so did the uses of die striking. By the late 1800s and early 1900s, lapel pins emerged as potent symbols of belonging, achievement and affiliation. Organizations, political movements and military groups were among the first to use metal lapel pins to communicate their identity and beliefs.

What started as a practical way to make durable items slowly became an art form. Antique lapel pins are now highly prized by collectors, not only for what they represent historically but also for their complex designs and beautiful metalwork. These pins offer a tangible connection to the past, reflecting the values and aesthetics of earlier times.

How They Are Made: The Die Struck Lapel Pin Manufacturing Process

Making die struck lapel pins requires specialized skills and equipment. I will provide a breakdown of the steps:

- Artwork and Design: Everything starts with a concept. I work with clients to turn their ideas into designs that work for die striking. This means simplifying the artwork to ensure it can be accurately reproduced in metal.

- Die Creation: The die, a metal stamp that holds the reversed image of the design, is the most important element. The design is etched into a steel block with great precision. This die will be used to imprint the design onto the metal.

- The Stamping Process: A metal sheet, often brass, copper or iron, is placed under the die. A press then applies intense pressure, pushing the die into the metal. This creates a raised or recessed image, depending on the design. This creates the raised metal pins.

- Cutting and Shaping: After stamping, the individual pins are cut from the metal sheet using specialized cutting tools to ensure clean edges.

- Polishing and Plating: The pins are polished to remove imperfections and create a smooth surface. Plating is often applied to improve the pin’s appearance and strength. Typical plating options include gold, silver, nickel and bronze.

- Color Filling (Optional): While die struck lapel pins often show off the bare metal to highlight the intricate details, some designs use enamel color fills. The recessed areas of the pin are filled with enamel paint, then baked to harden and create a smooth finish.

- Quality Control: Each pin is carefully inspected to ensure it meets strict standards for quality and craftsmanship. This involves checking the metal, plating and color filling for any flaws.

One defining feature of die struck lapel pins is the absence of a clear epoxy coating, which is common on other pin types. This allows the metal’s texture to be fully appreciated.

These pins are popular for good reason:

- Durability: Made from strong metals such as brass and copper, these pins are built to last. The stamping process creates a durable product that can handle everyday wear.

- Timeless Appeal: The classic look of die struck pins makes them suitable for any event. They project professionalism and sophistication, making them ideal for corporate awards, service recognition and memorial gifts.

- High Perceived Value: The premium materials and careful craftsmanship of die struck pins contribute to their high perceived value. They make a strong impression and are often considered treasured keepsakes.

- Customization: These pins can be customized to include various designs, logos and messages. The ability to create raised and recessed areas allows for intricate details and a unique tactile experience.

- Versatility: They are perfect for corporate branding, employee recognition and special events.

These pins offer a unique combination of durability, visual appeal and perceived value, making them a good choice for those seeking a sophisticated emblem.

Die Struck Pins Versus Other Lapel Pin Choices

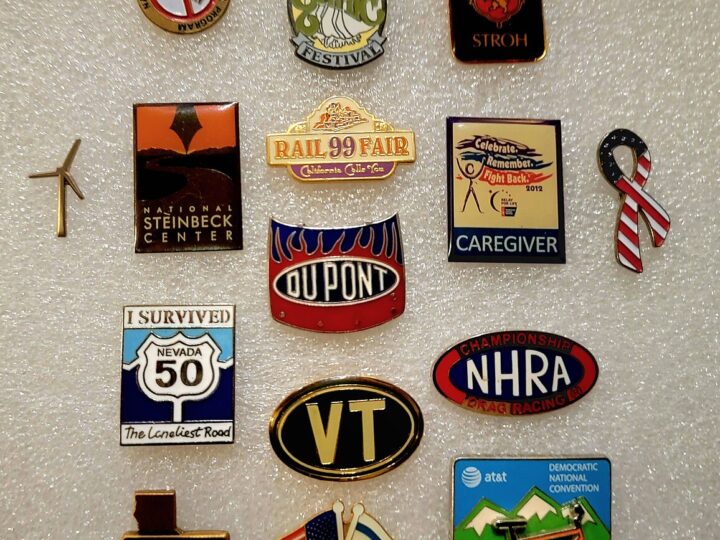

Understanding the differences between die struck pins and other types of lapel pins is important when deciding. Here is a quick comparison:

Die Struck versus Enamel Pins (Soft and Hard)

Enamel pins, including both soft and hard enamel types, involve filling recessed areas with colored enamel. Die struck pins often do not use color fills, instead relying on the metal itself to create the design. When color is included in a die struck pin, it typically does not have an epoxy coating.

- Appearance: Enamel pins have bright colors and smooth surfaces. Die struck pins have a more metallic look.

- Durability: While both pin types are durable, die struck pins are more resistant to scratching because they lack enamel.

- Cost: Enamel pins are often more cost effective for designs that use many colors.

Die Struck versus Printed Pins

Printed pins involve printing a design directly onto a metal surface. This method works for complex designs and photographs but does not have the depth and texture of die struck pins.

- Appearance: Printed pins can replicate detailed designs with many colors but lack the three dimensional quality of die struck pins.

- Durability: Printed pins are less durable than die struck pins, as the printed design can be scratched or fade.

- Cost: Printed pins are generally the most affordable option, especially for complex, multicolored designs.

Die Struck versus Offset Printed Pins

Offset printed pins are similar to printed pins, but the design is printed on a paper sheet first, then transferred to the metal surface. This technique provides better color accuracy and detail than direct printing but still lacks the depth and texture of die struck pins.

- Appearance: Offset printed pins provide better color accuracy than direct printing but still do not achieve the three dimensional effect of die struck pins.

- Durability: Offset printed pins are more durable than directly printed pins but are still less durable than die struck pins.

- Cost: Offset printed pins are more expensive than directly printed pins but less so than die struck pins.

Ultimately, the best choice depends on the desired look, budget and the required level of durability. If you want a classic, durable emblem, die struck lapel pins are a great choice.

Designing Your Die Struck Lapel Pins: Important Things to Keep in Mind

Creating a good design for your die struck pins requires careful thought. I often tell clients to remember these points:

- Simplicity: Complex designs might not translate well into metal. Simplify your design to emphasize the most important parts.

- Line Weight: Consider the thickness of the lines in your design. Thin lines might be difficult to reproduce, while very thick lines can look awkward.

- Text: If your design includes text, make sure it is easy to read. Choose a clear font and avoid too many words.

- Metal Finish: Choose a metal finish that complements your design. Gold and silver finishes give a classic look, while antiqued finishes can create a vintage feel.

- Color (If Applicable): If you plan to use enamel color fills, choose colors that contrast well with the metal finish. Consider the overall color scheme of your brand.

I help my clients with these design considerations to create die struck pins that accurately represent their brand.

Getting the Most Impact: Best Uses for Die Struck Lapel Pins

Die struck lapel pins are versatile emblems with many uses. Here are some of the most common:

Corporate Recognition

Recognizing employee contributions is important for building morale and creating a good work environment. Die struck pins are excellent service awards, recognizing years of service and good performance. They can also commemorate important events, such as the launch of a new product or the company’s anniversary.

Branding and Promotion

Lapel pins are a subtle way to promote your brand. Die struck pins can be customized with your company logo and colors, creating a wearable advertisement that employees, customers and partners can wear. They can also be given out at trade shows and conferences to increase brand visibility.

Membership and Affiliation

Groups, clubs and associations often use lapel pins to show membership. Die struck pins provide a unique way to demonstrate belonging. These pins can be designed with the group’s logo, colors and symbols, promoting a sense of unity among members.

Commemorative Events

Die struck pins are a lasting way to commemorate special events, such as anniversaries and historical occasions. These pins can be designed to capture the event, serving as a cherished memento. They can also be sold as souvenirs to raise money for a cause.

Fundraising and Awareness

Lapel pins can be used to raise money for charitable causes. Die struck pins offer a tangible way for supporters to show their support. These pins can be designed with the organization’s logo, colors and symbols, promoting a sense of solidarity.

Keeping Them Looking Great: Caring for Your Die Struck Lapel Pins

To keep your die struck pins looking good, proper care is important. Here are some tips:

- Storage: Store your pins in a cool, dry place away from sunlight. Use a pin display case or a soft pouch to protect them from scratches and dust.

- Cleaning: Clean your pins with a soft cloth to remove any dirt. Do not use harsh chemicals, as these can damage the metal finish.

- Handling: Handle your pins with care to avoid bending them. When attaching a pin, use a gentle twisting motion to avoid damaging it.

- Polishing (If Necessary): If your pins become dull, you can use a metal polish to restore their shine. Make sure to follow the instructions.

The Lasting Impact of Die Struck Lapel Pins

Die struck lapel pins combine artistry, craftsmanship and functionality. Their history and diverse uses make them a great choice for those seeking a durable emblem. Whether used for corporate recognition, branding or special events, these pins offer a lasting way to express identity. By appreciating their qualities, you can create metal lapel pins that truly represent your brand for years.