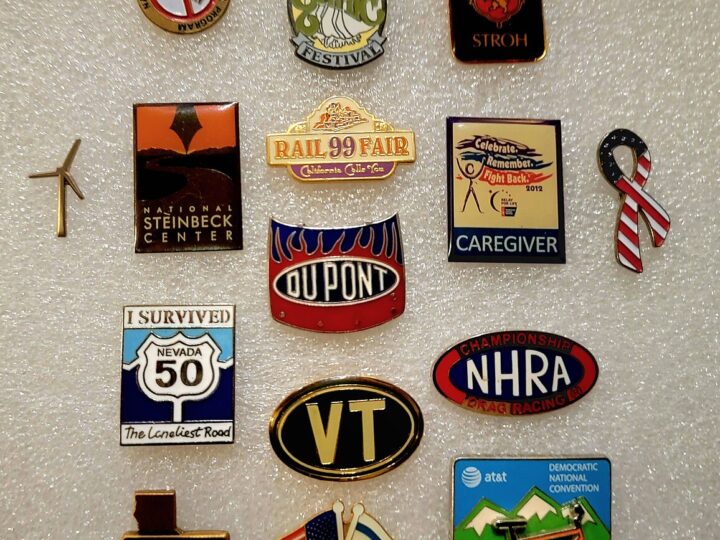

Did you know the right material can make or break your custom lapel pin? It is true! When making these tiny symbols for businesses, events or just to show off your personality, what you use matters a lot. It affects how long the pin lasts, how good it looks and how much people value it. I have seen projects really take off or totally fail just because of this one choice. Getting the materials right ensures your design pops and sticks around.

There is a huge selection of custom pin materials. Do not worry! I am going to walk you through it. I have spent years making great pins for all sorts of clients. I will share what I know about everything from basic metals to cool enamel finishes. This will allow you to pick what is best for you.

Why Lapel Pin Materials Are Important

Before we get into the details, let us talk about the basics. Lapel pins are mostly made of metals and enamels. Metals give the pin its shape, strength and ability to last. Enamels add color, small details and make it look good. Together, they create the pin’s personality and how good it is.

Metal Choices: The Base of Your Metal Pins

The metal you pick really changes how your metal pins look, feel and how long they last. Here is a look at the most common choices:

- Brass: This is a common and cheap option. Brass is strong and has a nice, warm gold color. It works well for detailed designs and is often used as a base for enamel. I often use brass because it is easy to work with and resists rust.

- Copper: Copper has a reddish color and conducts electricity well. It is a high quality metal that gives lapel pins a fancy feel. It costs a bit more than brass, but it is better at resisting rust. I once made copper pins for a historical group, and they looked amazing.

- Iron: Iron is known for being strong and cheap. It is often used in stamped pin designs. However, it does not resist rust as well as brass and copper, so it needs a protective coating.

- Zinc Alloy: Zinc alloy is flexible and affordable. You can make more complex shapes with it. It is also lightweight, making it good for larger pins.

- Stainless Steel: Stainless steel is valued for its strength and resistance to rust. It is a great choice for pins that will be used in tough situations. It has a modern, industrial style.

- Precious Metals (Gold, Silver): Gold and silver make pins look expensive and valuable. They are great for high end or special occasion pieces. These metals are often used in limited edition designs or awards.

Enamel Choices: Adding Color and Detail to Your Enamel Pin Materials

Enamel is like colored glass that is stuck to the metal part of the pin. It makes your design come to life with bright colors and small details. The world of enamel pin materials has two main types of enamel:

- Hard Enamel (Cloisonné): Hard enamel is heated to high temperatures and then polished to make it smooth. This makes it last a long time and resist scratches. The colors are separated by fine metal lines, which makes the design clear.

- Soft Enamel: Soft enamel is also heated, but it is not polished completely. This leaves the metal lines raised, which adds texture and depth to the design. Soft enamel pins are usually a cheaper option than hard enamel pins.

Things to Think About When Picking Lapel Pin Materials

Picking the right material requires some thought. Let us look at the important things:

Budget Considerations for Your Custom Pin Materials

How much you want to spend will really affect your material choices. Brass, iron and zinc alloy are usually the cheapest options. Copper, stainless steel and precious metals will cost more. Soft enamel is generally cheaper than hard enamel. I always tell clients to decide on a budget first to make the decision easier.

Design Complexity and Material Suitability

Detailed designs might need certain materials. For example, hard enamel (cloisonné) is great for designs where the colors are clearly separated. Soft enamel works better for more subtle shading. Zinc alloy is good for three dimensional designs. Very fine lines or small details might be better for die struck or printed pins, which are more precise.

Achieving Your Desired Aesthetic

Think about how you want the pin to look and feel. Do you want a classic, fancy pin with a smooth, shiny surface, or a tougher pin with a vintage feel? The material and enamel will determine the final look. A polished brass pin will look very different from a matte stainless steel pin.

Durability Requirements for Long-Lasting Pins

If your pins will be used in tough conditions or worn often, they need to be durable. Stainless steel and hard enamel are very resistant to scratches, rust and fading. If the pins are for outdoor events or everyday use, it is worth it to invest in strong materials.

Target Audience and Material Preferences

Think about who will be wearing the pins. Are they employees, customers or members of a group? The material should match what they expect and prefer. For example, if you are making pins for a luxury brand, precious metals or high quality copper might be the best choice. I once designed stainless steel pins for a tech company to show off their modern style.

Manufacturing Process and Material Compatibility

Different materials need different production methods. For example, die striking works best with metals like brass and copper, while casting is often used for zinc alloy. Knowing how it is made helps you pick the right material for your design. I work closely with manufacturers to get the best results.

Popular Material Combinations for Lapel Pins

Let us look at some popular material combinations and what is good about them:

Brass with Hard Enamel (Cloisonné): A Classic Combination

This combination has been used for a long time. It is strong, affordable and looks good. The brass base is solid, and the hard enamel makes it smooth and shiny. This combination is good for many designs and purposes. I often suggest this for company pins and awards.

Brass with Soft Enamel: A Cost-Effective Alternative

This combination is a cheaper option than brass with hard enamel. The soft enamel adds texture and can handle more detailed designs, but it is not as durable as hard enamel and can scratch more easily. This combination works for marketing pins and event giveaways.

Zinc Alloy with Soft Enamel: Ideal for Complex Designs

This combination is a cheap option for larger pins or pins with complex shapes. Zinc alloy is lightweight, so you can make more elaborate designs. Soft enamel adds color and details. This combination is often used in custom shaped pins and novelty items.

Stainless Steel with Printed Design: Perfect for Fine Details

If you have designs with photos or very small details, stainless steel with a printed design is very clear. The image is printed right onto the stainless steel and covered with a protective coating. This combination works well for memorial pins and badges.

Taking Care of Your Lapel Pins

No matter what material you pick, you need to take care of your lapel pins to keep them looking good. Here are some tips:

- Store your pins in a dry, cool place: Keep your pins away from heat or moisture, which can cause rust or fading.

- Clean your pins regularly: Gently wipe your pins with a soft cloth and mild soap. Do not use harsh chemicals because they can damage the enamel or metal finish.

- Handle your pins with care: Do not drop or bend your pins because this can damage the enamel or metal base.

- Consider a protective coating: If your pins will be in tough conditions, think about adding a protective coating to protect them from rust or fading.

Case Studies: Lapel Pin Material Choices in Action

Let us look at some real examples to see how important material selection is:

Case Study 1: Corporate Recognition Using Brass Pins

A big company wanted to give recognition pins to employees to thank them for their years of service. They chose brass pins with hard enamel (cloisonné) because they wanted pins that were strong and high quality and would last for years. The hard enamel made the surface smooth and polished, and the brass base added a touch of class. The pins were given to employees at an annual awards ceremony and were highly valued as symbols of their hard work.

Case Study 2: Promotional Event Pins Using Zinc Alloy

A nonprofit group needed pins to promote a fundraising event. They picked zinc alloy with soft enamel because they needed a cheap option that could be made in large numbers. The soft enamel made the design colorful, and the zinc alloy base kept costs down. The pins were given to people at the event and helped raise awareness for the group’s cause.

Future Trends in Lapel Pin Materials

The world of lapel pin materials is always changing, and new things are coming out all the time. We are seeing more use of sustainable materials, along with better enamel and printing methods. I keep up with these changes to give my clients the newest options.

One thing is using recycled metals to make lapel pins, which helps reduce waste and lessen the environmental impact of making them. Another thing is making new enamels that are stronger and more resistant to scratches and fading.

Making the Right Choice for Your Custom Lapel Pins

Picking the right material for your custom lapel pins is important because it affects how the pin looks, how long it lasts and how much people value it. Carefully think about your budget, how detailed the design is, how you want it to look and who will be wearing it. This will help you pick the material that works best for you. I hope this information has given you the knowledge to make a smart decision.

I am here to help you design the perfect lapel pin when you are ready. By carefully picking your custom pin materials, you can create something that lasts and represents your brand, message or personal style.